Parts of a Chain Sling Assembly

Chain slings are one of the most durable lifting slings on the market. In addition to their durability, their main attraction is that, unlike other types of lifting slings, chain slings are adjustable.

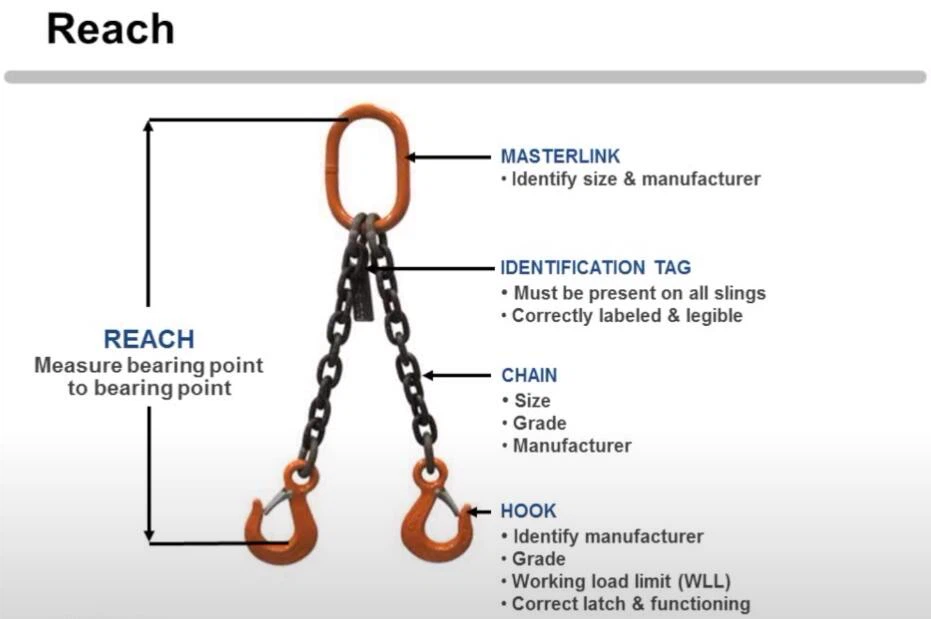

The acronyms used in chain sling abbreviations are defined by the parts present on the sling assembly. So, before we explain how to correctly abbreviate the name of a chain sling, we want to clarify what the different parts are.

A chain sling assembly may have one, two, three, or four legs. Each chain sling has one master link and, depending on the number of legs, one, two, three, or four lower end hooks.

On multiple-leg sling assemblies, the individual legs are attached to each other using a multi master link as the upper end fitting. Lower fittings on the end of each sling leg are used to connect the sling to the load, which are typically a type of hook.

Identification Tag

Any sling used for overhead lifting is required to have an identification tag. According to EN/AS standard, each chain sling shall be marked to show:

Name

Grade

Nominal chain size

Number of legs

Working load limit

Length (reach)

Serial number

Manufactured date

Upper fitting

Upper fitting is most common to see an master link or multi master link on a chain sling assembly.

Chain Sling Legs

A chain sling may have one, two, three, or four legs attached to the master link.

Lower end fittings

More often than not, the lower end fittings at the end of each chain sling leg will be hooks. The most commonly used types of sling hooks on a chain sling assembly are:

Sling hooks

Grab hooks

Self-locked hooks